- Pick and place robot for waver production

- waterproof small robots for machine tools

- Cleanroom robots for food and pharmaceutical industry

- Palletizing robots for various handling tasks

- Lightweight robot for human-machine cooperation

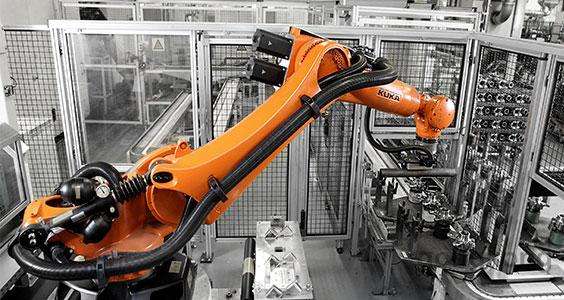

- Industrial robots for automotive production, welding robots

- medical robots for surgical technology

- Inspection robots for pipelines and pipes

APPLICATIONS

The various Ingiant slip ring series are optimised for a wide range of applications.

Aerospace:Aircraft pods, satellite solar panels,Seeker etc.

Main supporting products:Electrical rotary connector, optical rotary connection device, electro-optical combination rotary connector,Microwave rotary connector, etc.

The reliability and working life of the aerospace conductive slip ring are related to the success or failure of the aircraft’s in-orbit flight mission. It is one of the few single-point failure devices on various spacecraft.

Once a failure occurs, it will often cause energy loss and even disaster. sex accident. Long working life and maintenance-free: As a part of the satellite, the conductive slip ring plays a key role in transmitting various energy and electrical signals for the satellite. Satellites have been in orbit for a long time, so aerospace slip rings must have a long life, and due to the space environment, they need to be able to withstand high and low temperatures and be maintenance-free.

Play Equipment:Ferris wheel, carousel, VR game console, etc.

Main Supporting Products:Conductive slip ring

Common merry-go-round horses in amusement parks, when the merry-go-round horse starts to rotate, it will be accompanied by beautiful music and romantic lights, so how to solve the problem of uninterrupted transmission of electrical energy and signals while rotating, this time requires The conductive slip ring is used to complete such work. The stator is connected to the bottom, which is stable, and the rotor is connected to the shaft, which rotates to solve the problem of wire winding. There is a copper ring brush wire inside the slip ring, which can complete the transmission of electricity, signals, Data and other needs.

Many large-scale amusement facilities need conductive slip rings to work together. For example, Ferris wheels also have rotation requirements such as signal transmission. Generally, such equipment will use collector rings, which are wear-resistant and have a long life; or they can be used according to the equipment. Customized conductive slip rings.

slip rings for robotics

Industrial robotics is still on the advance. In manufacturing processes, the automation rate is increased worldwide, often optimizing the corresponding costs. Robots are the heart of modern production lines in almost all branches of industry. They take on complex tasks and can be used highly efficiently and flexibly.

Typical robot applications for slip rings:

slip rings for Packaging and filling machines

Slip rings are widely used in mechanical equipment such as packaging and filling, which can greatly improve production efficiency, liberate manual productivity, and adapt to modern and mass production needs. The use of waterproof conductive slip rings in fully automatic or semi-automatic filling equipment can further meet the requirements of national hygiene standards. Through-hole slip rings are commonly used in beer and beverage filling machine accessories, and through-hole conductive slip rings are also commonly used in paper packaging machines, food packaging machines, and pillow packaging machine accessories. Medical equipment accessories that have higher requirements for packaging and filling are recommended. Mercury slip ring or new direct type slip ring.

☛Packaging machines for food

☛Packaging machines for pharmacy

☛Packaging machines for cosmetics

☛Thermoforming lines for the packaging of food and non-food articles in a protective atmosphere

☛Filling systems

☛Mechanical palletizing systems

☛Robot controlled palletizing systems

☛Stretch Packer

☛Shrink film machine

☛Cartoning systems

slip rings for cranes

Slip rings are also used in crane technology for power and data transmission. Depending on the different types of machines, different tasks in crane technology are connected with the rotary transmissions. Under heavy duty conditions, all rotating components of the cranes (e.g. jib arms and grabs) must be reliably supplied with power and data in indoor and outdoor applications. The enormous reliability of the slip rings plays a major role, especially with high loads that are suspended above man and machine.

Common Applications for Slip Rings in CraneTechnology:

Bucket wheel excavator in opencast mining

Bucket wheel excavator in opencast mining

Advantages of slip rings in crane technology

◐ Compact size, easy installation, high reliability and long operating time

◐ Transmission of fieldbus signals: Profibus, Profinet, CANopen

◐ Data transmission via optical fibre

◐ Schutzart up to IP68, suitable for use in dusty and exposed environments

◐ Noble contact materials, high conductivity, low starting torque

◐ Shock-resistant design, can also be used with high vibrations

◐ Extremely temperature resistant

New energy equipment

Exhibit equipment

Monitoring equipment

Testing Equipment

Get In Touch

We will be happy to answer any questions and look forward to hearing from you