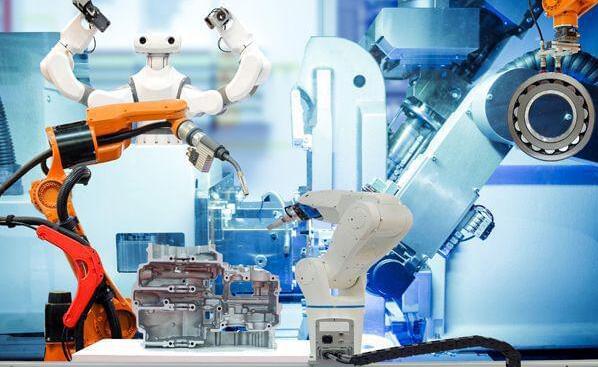

Application and characteristics of conductive slip ring for automated manipulator

Automated robotic arms usually use conductive slip rings (also known as rotary joints, rotary contactors), which allow the robotic arm to transmit power, signals and data as it spins and turns.

Robotic arms generally use hollow shaft slip rings or hollow rotary joints to transmit signals and power. This can make the movement of the robot arm more stable, and can also avoid signal interference or disconnection caused by the winding of the cable. In addition, some robotic arms use hydraulic or pneumatic slip rings for transmission. Conductive slip rings are usually made of metal alloys, conductive carbon materials, and plastics for high reliability and long life.

Among them, the production process of metal alloy is relatively complicated, but it has better performance and reliability, and can meet the application scenarios with high requirements such as high speed and high precision; while conductive carbon materials and plastics are usually suitable for low load, low precision, etc. Less demanding application scenarios.

The mechanical arm slip ring is a kind of transmission device in the mechanical arm, which has the following characteristics:

1.High-precision transmission:ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ The slip ring of the robotic arm can realize precise rotation transmission, ensuring the precision and stability of the robotic arm movement.

2.Large rotation angle range: The slip ring of the robotic arm can realize a 360-degree infinite rotation angle range, which can meet the flexibility requirements of the robotic arm in various working scenarios.

3.Strong load capacity: The slip ring of the robotic arm can withstand a large load, ensuring that the robotic arm can still operate normally under heavy load conditions.

4.Long life and wear resistance: The slip ring of the mechanical arm is made of high-quality materials and precision manufacturing process, which has a long service life and strong wear resistance.

5.Easy maintenance: The slip ring of the robotic arm has a simple structure and is easy to maintain, which can reduce the downtime and maintenance costs of the robotic arm.