Precautions for installing servo motor slip rings

AC servo motors are also brushless motors, which are divided into synchronous and asynchronous motors. Synchronous motors are generally used in motion control. They have a wide power range and can achieve very high power. Most servo motors are synchronous motors, which have a wide power range and can achieve very high power. They have large inertia, low maximum rotation speed, and decrease rapidly as power increases. Therefore, they are suitable for applications with low-speed and stable operation. The following slip ring manufacturers will tell you about the precautions for installing servo motor slip rings.

When installing the servo motor slip ring, do not apply direct impact to the shaft to avoid shaft damage. Do not overload the bearing, as overload has a great impact on the bearing life. It is recommended that the bearing load is smaller than the specified load, which can greatly extend the bearing life.

When installing the connector on the shaft, be careful not to force it in. If it is not installed properly, a load greater than the allowable load may be applied to the shaft, or the core may be pulled out.

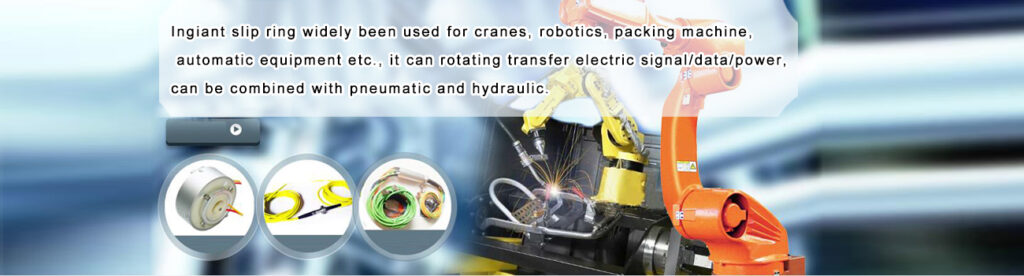

The slip rings produced by Ingiant Technology are widely used in high-end automation equipment and various occasions that require rotation and conduction. The products have the advantages of long life, strong anti-interference ability, and good electromagnetic compatibility. The business covers maritime, medical, robotics, wind power, security, engineering machinery, heavy machinery, and instrumentation. It can be said that as long as electrical equipment and equipment that require 360-degree rotation are needed, Ingiant slip rings can be seen. The R&D team is strong, the production capacity is strong, the delivery cycle is short, and it can be designed and produced on demand. If you have any needs, please contact us.