Principles and characteristics of separate conductive slip rings

A separate conductive slip ring refers to a conductive slip ring that separates the rotor and the stator. The stator is generally a contact brush, and the rotor is generally used as a connection channel for conductivity, gas, and liquid. The biggest advantage of separate conductive slip rings is that they are flexible and simple, can better adapt to space constraints, and meet some specific installation requirements and special installation environments.

It can be installed in various ways such as cap flange, hollow hole or divided into several groups. The corresponding ones are divided into separated cap type conductive slip ring, separated hollow shaft conductive slip ring, separated disc type conductive slip ring and separate type. Special-shaped conductive slip rings, their specifications can be as small as a few millimeters, and the diameter of large ones can reach several meters or even larger.

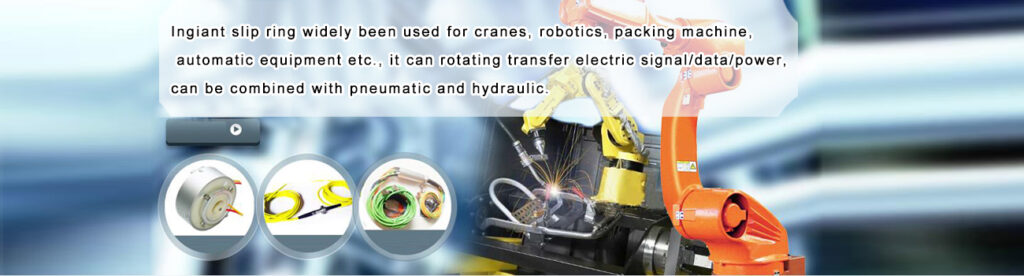

Separate conductive slip rings are widely used in various mechanical equipment, especially those that require continuous rotation or frequent rotation. It has important application value in industrial automation, medical equipment, robotics, stage lighting, photography equipment and other fields. The outstanding performance and stable transmission characteristics of separate conductive slip rings provide efficient and reliable power supply for equipment in these fields.

With the continuous advancement of science and technology, INGIANT technology separated conductive slip rings are also constantly innovating and improving. In the future, we can look forward to the emergence of more efficient, environmentally friendly and intelligent conductive slip rings. For example, separate slip rings using new materials and advanced technology can further improve the efficiency and stability of power transmission while reducing energy loss and the volume and weight of the slip ring.