100mm through-hole large inner bore slip ring

100mm through-hole slip ring

100mm through-hole slip ring offers a range of advantages and applications. It allowing for the transmission of electrical signals and power between rotating and stationary parts.

When selecting a 100mm through-hole slip ring, it is crucial to consider factors such as the number of electrical circuits required, the type of signals being transmitted, the operating speed, and the environmental conditions. Customization options are often available, allowing for specific configurations to meet the unique requirements of a particular application.

The design of a 100mm through-hole slip ring is critical to its performance and reliability. High-quality slip rings are constructed using advanced materials and precision engineering techniques to ensure smooth and uninterrupted rotation. They are typically made of durable metals like stainless steel or aluminum, ensuring longevity and resistance to wear and tear.

100mm through-hole slip ring from Ingiant

100mm through-hole slip ring is named after its inner diameter, which measures 100mm.The large inner hole size makes it ideal for applications that require the passage of fluid, gas, or other media through the center of the slip ring. It provides a pathway for hydraulic lines, pneumatic tubes, fiber optics, or other components that need to pass through the rotating axis.

One of the primary advantages of a 100mm through-hole slip ring is its ability to handle a significant number of electrical circuits. It can accommodate numerous signal and power lines, allowing for the transmission of high-speed data, control signals, and power supply simultaneously.

To maintain electrical continuity and minimize signal loss, the slip ring’s brushes and rings are made from high-quality materials, such as noble metals like gold or silver. These materials offer excellent electrical conductivity and low contact resistance, ensuring reliable transmission of signals and power across the rotating interface.

Additionally, 100mm through-hole slip rings are designed to operate under varying environmental conditions. They can withstand extreme temperatures, humidity, and exposure to oil, chemicals, or other harsh substances. This feature makes them suitable for use in both indoor and outdoor applications, where reliability and durability are essential.

In conclusion, the 100mm through-hole slip ring is a versatile and essential component in various electromechanical systems. With its large through-hole size, it enables the passage of fluids or other media while transmitting electrical signals and power between rotating and stationary parts. Its ability to handle numerous circuits and its robust design make it suitable for demanding applications across industries. So, whether it’s in robotics, wind turbines, or medical equipment, the 100mm through-hole slip ring plays a crucial role in enabling reliable and efficient operation.

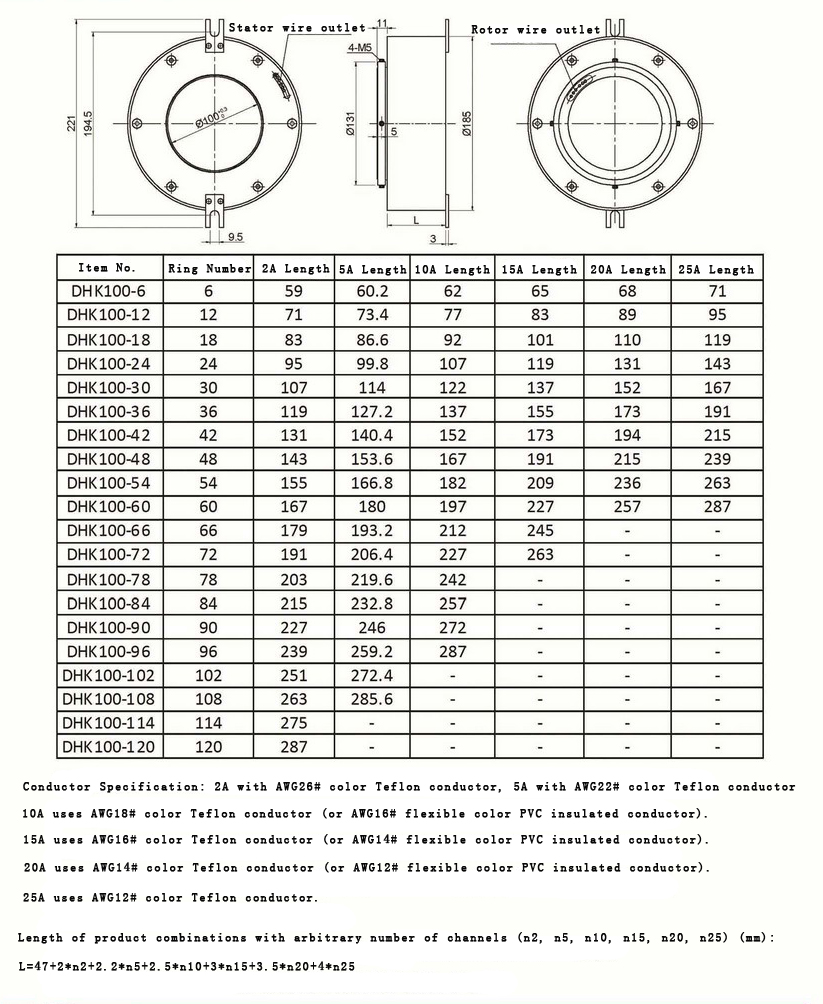

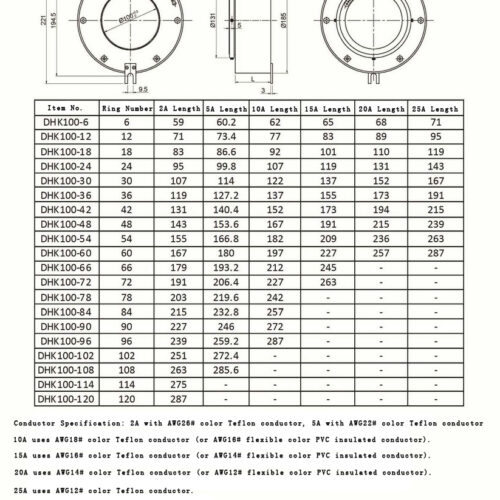

| DHK100 | |||

| The main parameters | |||

| Number of circuits | According to requirement of customers | Working temperature | “-40℃~+65℃” |

| Rated current | 2A,5A,10A,15A,20A | Working humidity | <70% |

| Rated voltage | 0~240 VAC/VDC | Protection level | IP54 |

| Insulation resistance | ≥1000MΩ @500VDC | Housing material | Aluminum Alloy |

| Insulation strength | 1500 VAC@50Hz,60s,2mA | Electrical contact material | Precious metal |

| Dynamic resistance variation | <10MΩ | Lead wire specification | Colored Teflon insulated & tinned stranded flexible wire |

| Rotating speed | 0~600rpm | Lead wire length | 500mm + 20mm |

Ingiant advantage:

1. Expertise and Experience: Ingiant have specialized knowledge and experience in designing, manufacturing, and testing slip rings. We have a deep understanding of the technical requirements and specifications needed for different applications. This expertise ensures that the slip rings produced are of high quality and meet the specific needs of customers.

2. Customization: Ingiant offer customization options to meet unique and specific requirements. We work closely with customers to design and manufacture slip rings that are tailored to their exact needs. This flexibility allows for the production of slip rings that are optimized for specific applications, ensuring optimal performance and reliability.

3. Quality Control: Ingiant have established quality control processes in place to ensure the production of high-quality slip rings. We have sophisticated testing equipment and procedures to verify the performance and durability of the slip rings before they are delivered to customers. This ensures that customers receive slip rings that meet the highest standards of quality and reliability.

4. Efficiency and Cost-Effectiveness: Ingiant are equipped with state-of-the-art machinery and production lines that enable efficient and cost-effective manufacturing processes. We have the capabilities to produce slip rings in large quantities, reducing production costs and lead times. This efficiency translates into competitive pricing for customers without compromising on quality.

5. Technical Support: Ingiant provide technical support and assistance to customers throughout the entire process, from design to installation and maintenance. We have a team of knowledgeable engineers who can offer guidance and expertise, helping customers select the right slip ring for their specific application and troubleshoot any issues that may arise.

Related products

Through bore slip rings

Through hole slip ring with aviation plug, hole diameter 85mm

Through bore slip rings

Ingiant small through hole slip ring hole 18mm for Oil Drilling Rigs

Through bore slip rings

Ingiant DHK083 series custom through hole slip rings bore size 80mm

Through bore slip rings

Through bore slip rings

Through bore slip rings

Ingiant DHK Series Through Bore Slip Ring Hole Size 14mm Mini

Through bore slip rings

Separate slip rings

2022.4.14-3-500x500.jpg)

2022.4.14-2-500x500.jpg)

2022.5.6-2-500x500.jpg)

2022.5.6-4-500x500.jpg)