Ingiant hydraulic rotary unions diameter 115mm 4 channels

Feature:

Hybrid rotary unions data/signal/power circuits with pneumatic and hydraulics

Compact structure

Can be customized specifications:

Number of electric circuits, pneumatic and hydraulic passages

Cable length

Working medium and working pressure of pneumatic and hydraulic passage

Rated speed

Typical application

Automatic welding machine system

Industrial filling equipment

Cooling equipment

Crane use combine with electric

|

Technical parameter |

|

| Passages | According to customer’s requirement |

| Thread | M5 |

| Flow hole size | 8mm diameter |

| Working medium | Hydraulic oil, or other liquid |

| Working pressure | 21Mpa |

| Working speed | <200RPM |

| Working temperature | -30°C~+80°C |

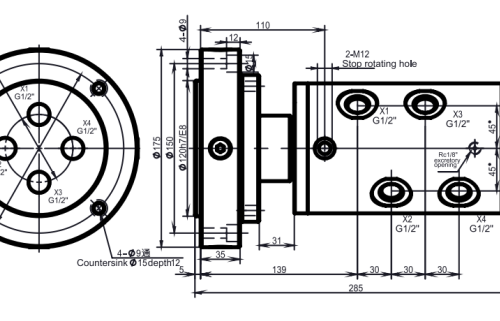

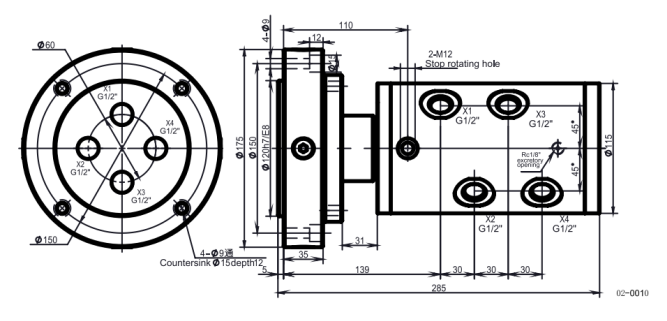

Product outline drawing:

Why slip rings and rotary unions are so important

That is why electromechanical slip rings and rotary unions still have something in common: they are the foundation of almost every industry, whether food production, medical technology and pharmaceuticals, chemical industry, agriculture, robotics or the paper industry.

At the same time, they are also often an important component in various vehicles such as chain excavators, cranes or agricultural vehicles. For example, rotary unions can be used for tire pressure control systems on large agricultural machines to transfer the compressed air. In large hydraulic chain excavators, they carry hydraulic fluid and return oil.

That’s why it always made sense to combine the function of rotary unions and slip rings. For example, with just one component, the pneumatic energy for the tire pressure could be transmitted to the tire and the data from the measured values in each individual tire could be transmitted back to the driver’s cab. Or, for example, not only direct the return oil to the appropriate container, but also transmit the filling level of the hydraulic oil container. That’s the purpose of hybrid pneumatic, hydraulic and electrical rotary unions. They allow a combined transmission of data, power, electrical signals, pressure, gas, air, fluids and more.

And this is very important for several myriad applications where space is always at a premium. From the powertrain of a wind turbine to military vehicles, to satellites and rockets. Saving space and weight is extremely important, but at the same time reliability and durability must not suffer.

Related products

Pneumatic+ liquid slip rings

Ingiant standard pneumatic rotary joint 2 channels for crane

Pneumatic+ liquid slip rings

Ingiant pneumatic rotary joint 8 channels for pneumatic equipment

Rotary joints