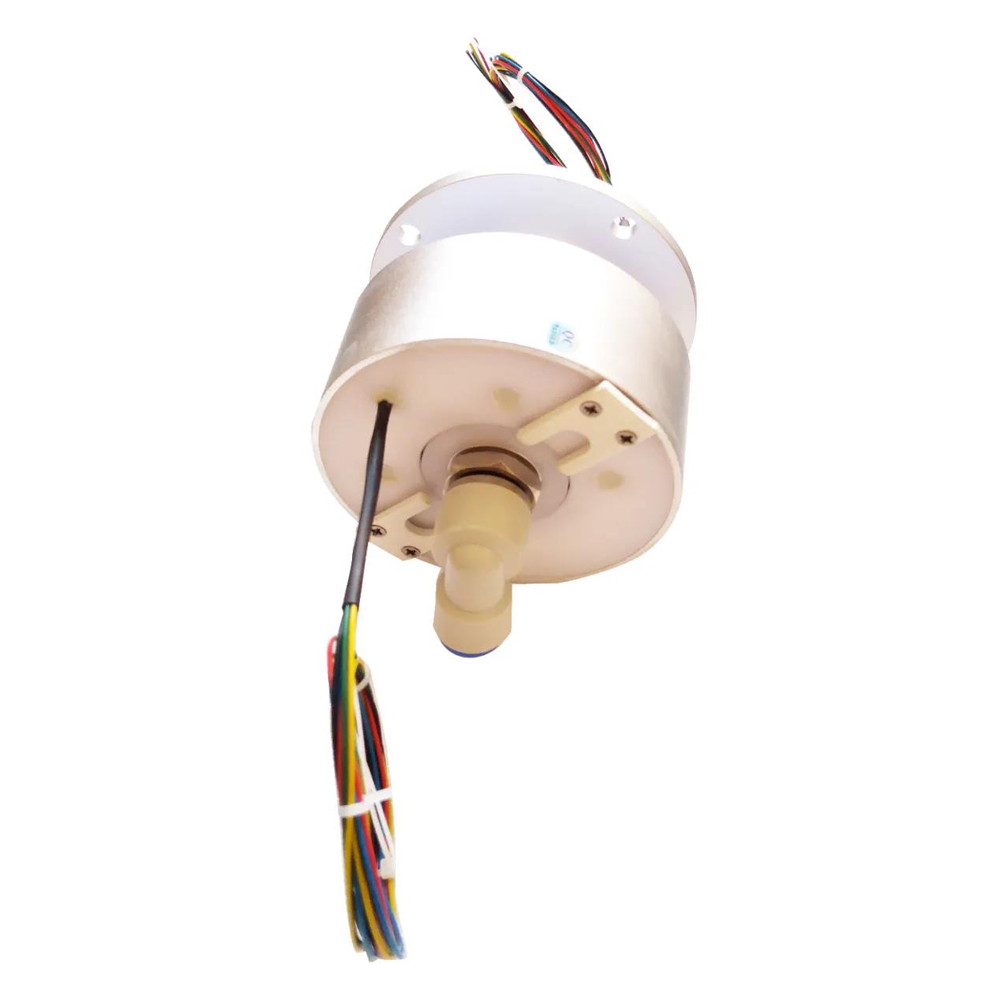

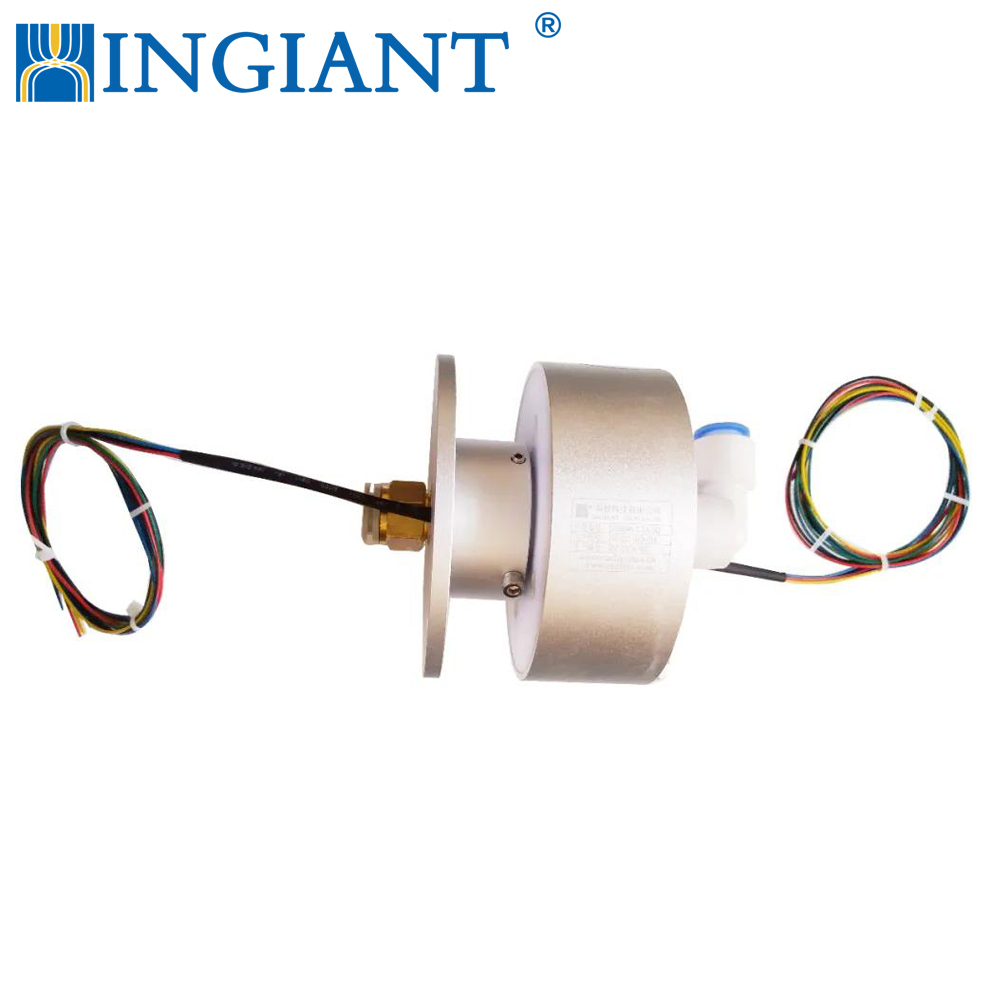

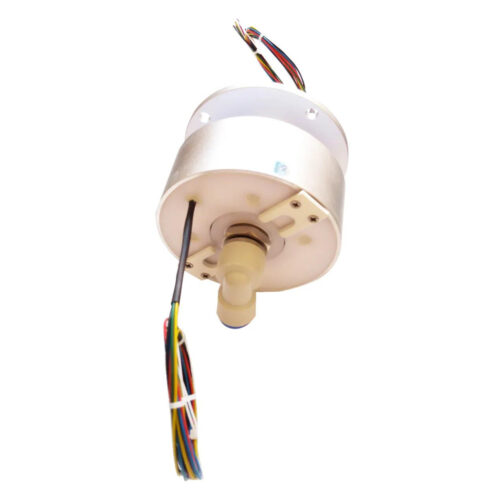

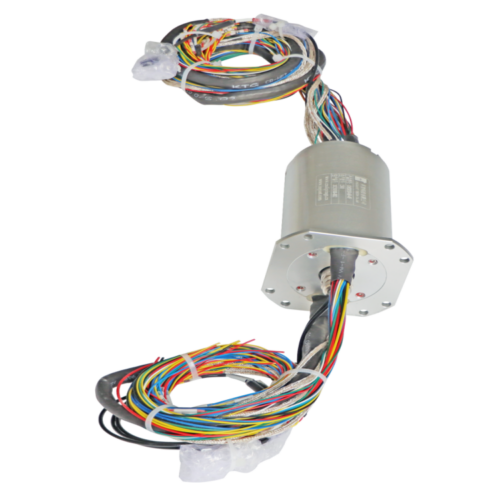

Ingiant 1 air tube pneumatic rotary joint slip ring

Ingiant slip ring products have compact structure, adopt precious metal contact points, stable data signal transmission, long life and maintenance free. They can be customized according to different needs of customers and provide professional solutions.

Ingiant top performance is ensured by attention to detail. These slip rings are built with metal-metal technology, that is, with brushes and rings covered in a layer of silver alloy; this allows disturbance-free electrical signals to be transmitted, ensuring ring duration of up to 208 revolutions without maintenance. The number of electrical circuits goes from a minimum of 1 up to a maximum of 50 with a capacity of up to 15 A and voltages of 600 VAC/VDC. Three versions of protection are available: the standard IP51 and 2 others in IP54 and IP65 version.