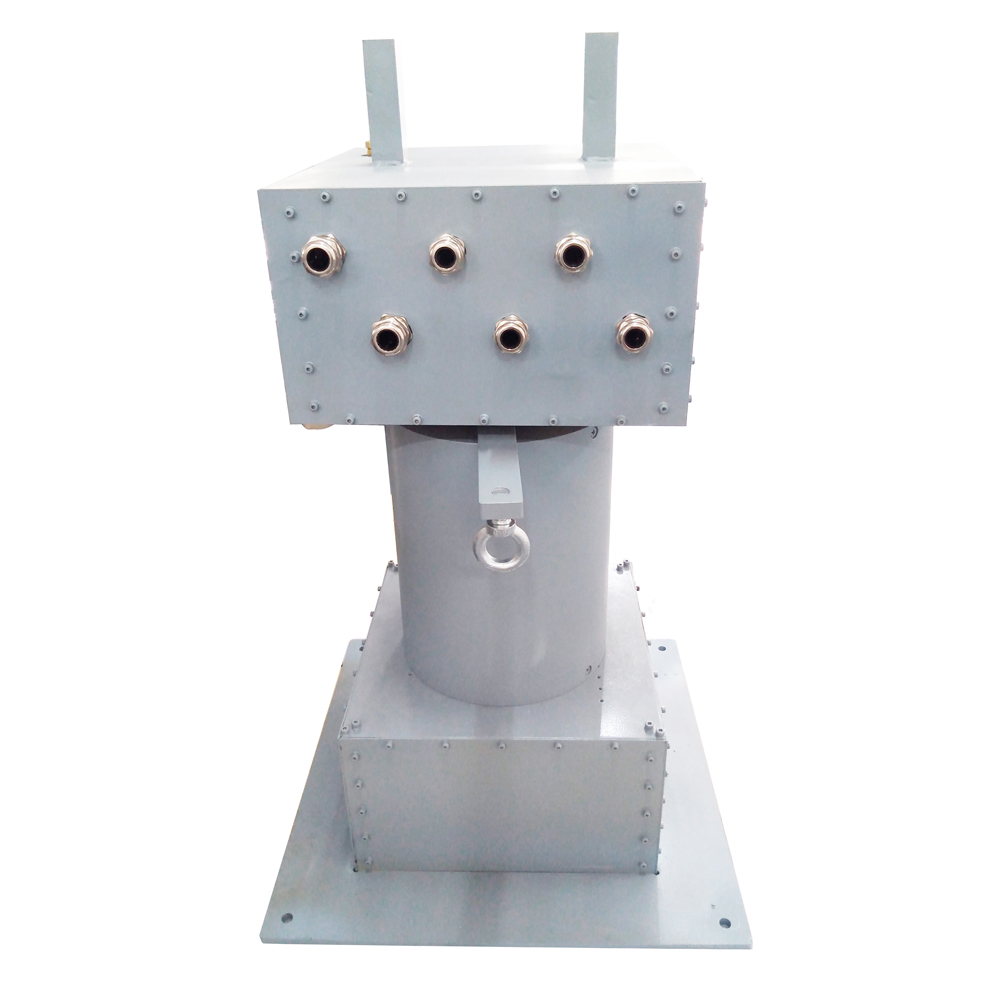

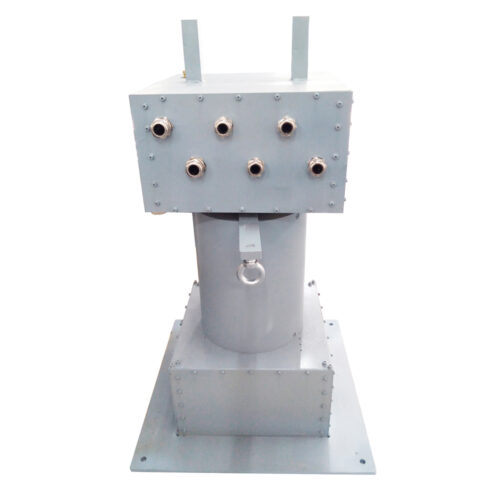

Ingiant customized slip ring 20 channels for LED display screen

HDMI is a high-definition multimedia interface. It adopts digital video and audio interfacetechnology. It is a special digital interface suitable for image transmission. It can transmit audio and video signals at the same time. It is widely used.HDMI slip ring can be used in military field in addition to LED display, so that soldiers can truly experience the battlefield environment visually and audibly; Or applied to the simulation industry, virtual reality technology can simulate the real environment, so that users can get realistic feelings, such as the game field, education and training, telemedicine, online shopping and so on.

Jiujiang Ingiant technology can also provide SDI high-definition slip ring, which can simultaneously transmit electrical signals, high-definition video signals and high-speed digital signals to meet the requirements of electromagnetic compatibility.

Ingiant have special technology to avoid the signals interference, please provide your required specifications, so we can provide solution for you accordingly.