Ingiant hybrid slip ring for gas liquid and electric transfer

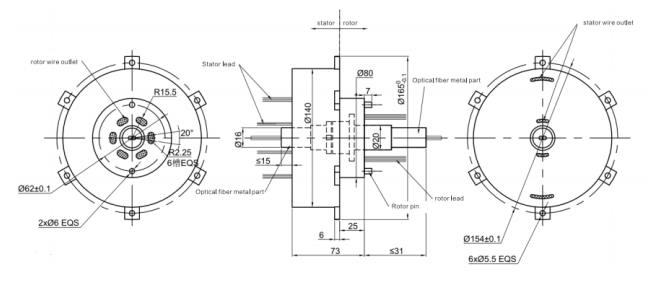

Hybrid slip rings Mechanical Specifications

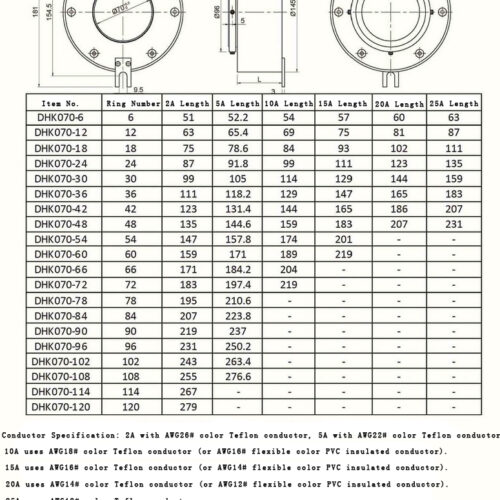

- Item No.: DHS085-26-2A-2Q

- Transmission type: low power signal combined with 2 channel of air rotary joint

- Current Rating: 2A each wire

- Voltage Rating: 220/440 VAC/VDC

- Outer diameter: 85mm

- Contact material: Gold-gold or Silver-silver

- Protection Level: IP51

- Wire Quantity: 26

- Rotation speed: 0~600RPM

- Material: Stainless Steel or aluminum alloy

- Installation type: flange install

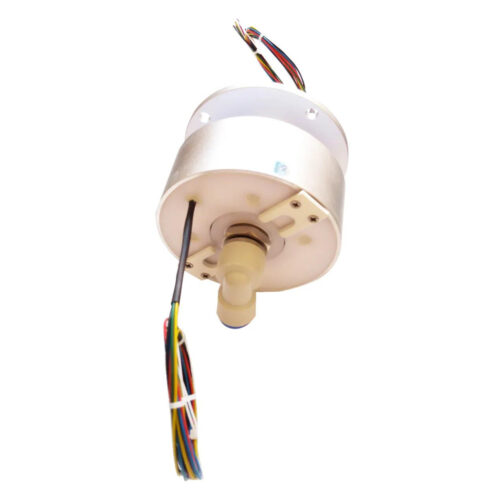

Product Description:

DHS series is our solid inner flange install slip ring series, it’s for industry automatic equipment, the function of DHS085-26-2A-2Q slip ring is to rotating transfer low current signal and air.

We also can make customized slip ring for rotating transfer HD-SDI, video signal, Data, gas, liquid and many other various types of power and signals.

If you are looking for an all-rounder among the slip rings, then you are well advised to choose our pneumatic liquid series. These slip rings offer you a 360° feed-through for all forms of media and energy that exist: Power current, signal current, pneumatics and hydraulics all find room in these compact but powerful slip rings. This gives you maximum design freedom in the smallest space for your applications.