High quality 12mm through hole slip ring

Through hole slip rings are commonly used in applications such as robotics, wind turbines, and surveillance cameras.

The term “through hole” refers to the central opening in the slip ring that allows for a shaft or other device to pass through it. This is useful in applications where the slip ring needs to be mounted directly onto a rotating shaft. Through hole slip rings come in a variety of sizes and configurations to accommodate different shaft diameters and electrical specifications.

When selecting a through hole slip ring, it is important to consider factors such as the number of electrical circuits required, the electrical current and voltage ratings, and the operating speed of the rotating object. It is also important to choose a slip ring that is compatible with the specific application and environment in which it will be used.

High quality 12mm through hole slip ring are electrical connectors that allow the transfer of power and signals from a stationary device to a rotating structure. As the name suggests, these slip rings have a hole in the center that enables cables and wires to pass through, making them ideal for applications where space is limited.

Through hole slip rings are commonly used in wind turbines, robotics, medical equipment, and other industrial machinery where continuous rotation is required. They come in different configurations, including single and multiple channels, and can handle a range of electrical currents and voltages.

Overall, through hole slip rings provide a reliable and efficient solution for transmitting power and data signals in rotating assemblies.

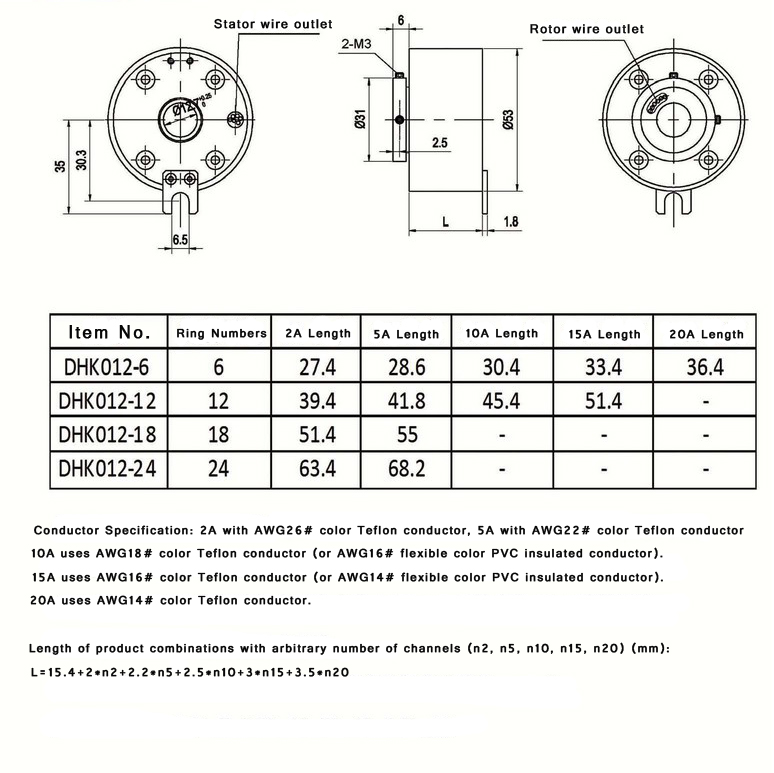

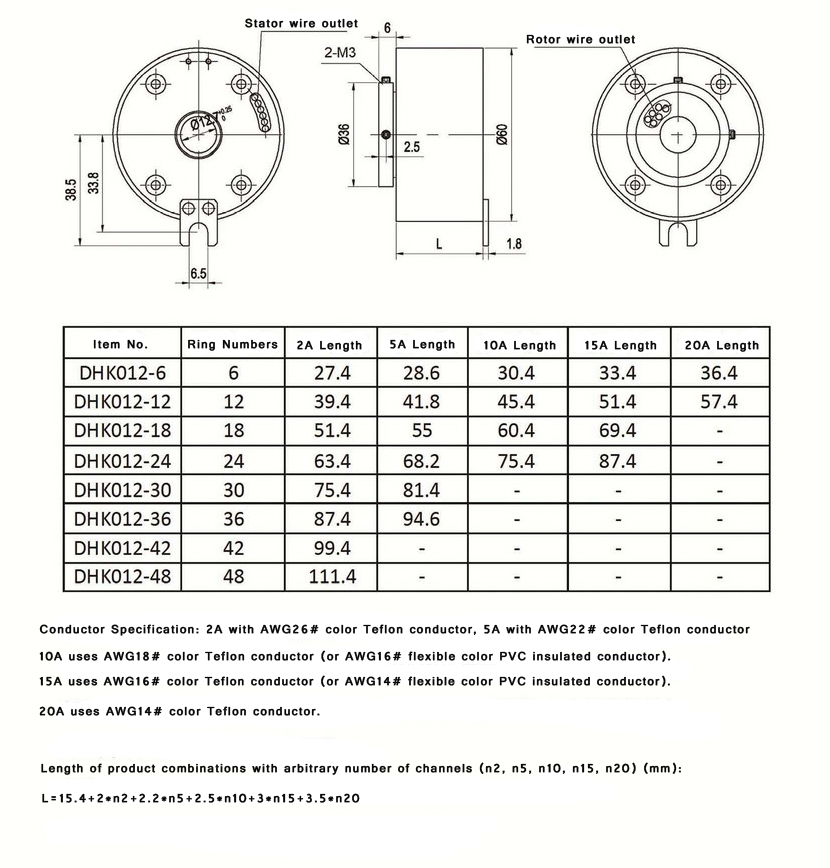

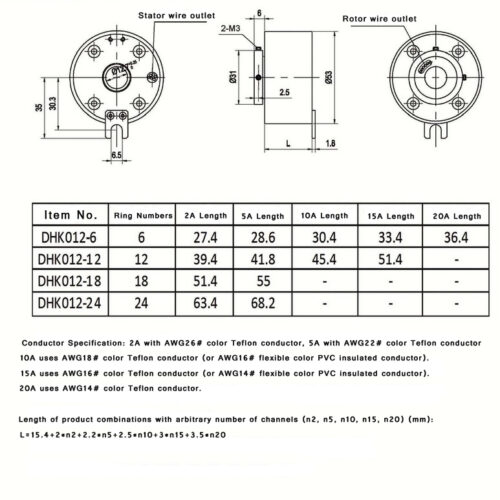

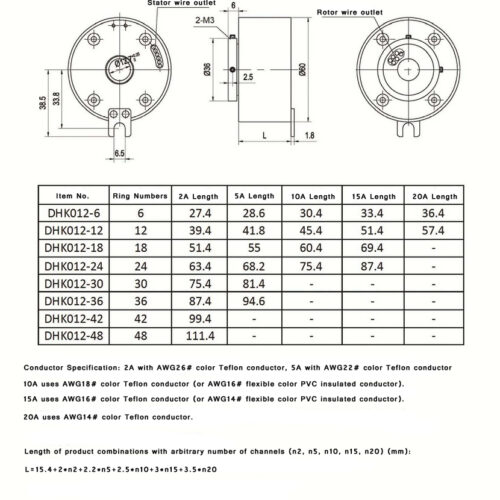

Ingiant standard through hole slip rings named DHK series, the inner hole diameter size from 12mm to 100mm, standard slip ring cost is more effective than customized items,

| DHK012-12-10A | |||

| Ingiant through hole slip ring | |||

| Number of circuits | 12 | Working temperature | “-40℃~+65℃” |

| Rated current | 2A.5A.10A.15A.20A | Working humidity | <70% |

| Rated voltage | 0~240 VAC/VDC | Protection level | IP54 |

| Insulation resistance | ≥1000MΩ @500VDC | Housing material | Aluminum Alloy |

| Insulation strength | 1500 VAC@50Hz,60s,2mA | Electrical contact material | Precious metal |

| Dynamic resistance variation | <10MΩ | Lead wire specification | Colored Teflon insulated & tinned stranded flexible wire |

| Rotating speed | 0~600rpm | Lead wire length | 500mm + 20mm |

| Product Size | Torque | ||

Ingiant factory advantage:

150 workers team, 25 engineers R&D team, 15 QC inspector team, full sets of CNC and QC inspection equipment

1.Expertise and Experience: Ingianthave specialized knowledge and experience in designing, manufacturing, and testing slip rings. Wehave a deep understanding of the technical requirements and specifications needed for different applications. This expertise ensures that the slip rings produced are of high quality and meet the specific needs of customers.

2.Customization: Ingiantoffer customization options to meet unique and specific requirements. Wework closely with customers to design and manufacture slip rings that are tailored to their exact needs. This flexibility allows for the production of slip rings that are optimized for specific applications, ensuring optimal performance and reliability.

3.Quality Control: Ingiant have established quality control processes in place to ensure the production of high-quality slip rings. We have sophisticated testing equipment and procedures to verify the performance and durability of the slip rings before they are delivered to customers. This ensures that customers receive slip rings that meet the highest standards of quality and reliability.

4.Efficiency and Cost-Effectiveness: Ingiant are equipped with state-of-the-art machinery and production lines that enable efficient and cost-effective manufacturing processes. We have the capabilities to produce slip rings in large quantities, reducing production costs and lead times. This efficiency translates into competitive pricing for customers without compromising on quality.

5.Technical Support: Ingiant provide technical support and assistance to customers throughout the entire process, from design to installation and maintenance. We have a team of knowledgeable engineers who can offer guidance and expertise, helping customers select the right slip ring for their specific application and troubleshoot any issues that may arise.

Ingiant slip ring advantage

1.Compact structure size, use high quality material, slip ring more durable

2.Excellent electrical performance, capable of transmitting up to 100MHz signals

3.High EMC performance, stable signal, packet loss rate less than 5%

4.Low friction and torque, long lifespan

5.Low dynamic resistance > 5mΩ

6.Provide a 10 million RPM or 12 month warranty

Related products

Through bore slip rings

Through hole slip ring super long life 6 channels 20A and 10 channels 2A

hybrid slip ring

Separate slip rings

Through bore slip rings

Ingiant through hole slip ring 3 channels 40A and 2 channels 10A

Through bore slip rings

Ingiant DHK series hollow shaft slip rings have 16 channels and bore diameter 48mm

Through bore slip rings

Through bore slip rings

Through hole slip ring with aviation plug, hole diameter 85mm

2022.5.6-2-100x100.jpg)

2022.5.6-2-500x500.jpg)

2022.5.6-4-500x500.jpg)