Semiconductor equipment slip ring is one of the core equipment in smart factories, and it plays a key role in the semiconductor manufacturing process. Semiconductor equipment slip ring generally refers to a rotary joint system used to transmit power, signals and liquid media between rotating parts and keep the rotating parts running continuously. The following is an analysis of semiconductor equipment slip ring:

- Function: The main function of semiconductor equipment slip rings is to achieve power transmission, signal transmission and medium flow between rotating parts. In the semiconductor manufacturing process, rotating parts (such as workpiece tables, slicing disks, etc.) need to be connected with stationary parts (such as power supplies, sensors, etc.). Semiconductor equipment slip rings achieve stable power and signal transmission by providing brushes and annular contact surfaces, while supporting the delivery of liquid media.

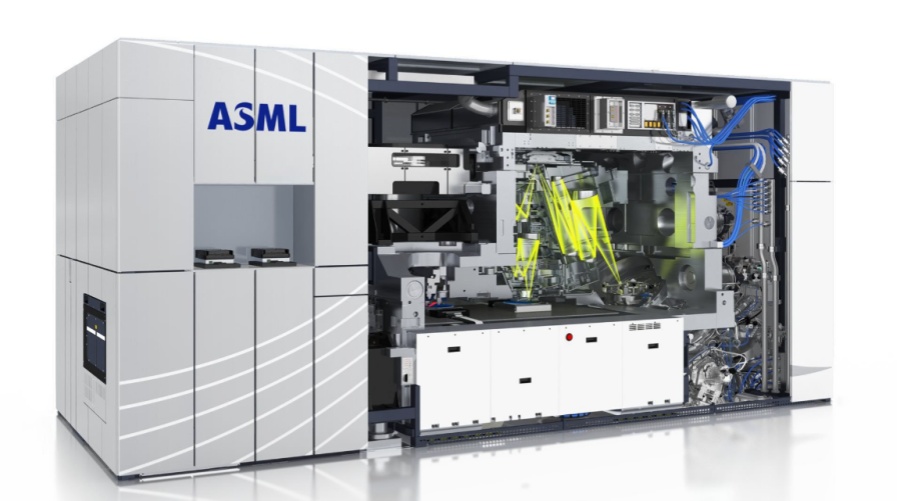

- Application: Semiconductor equipment slip rings are widely used in various links of semiconductor manufacturing equipment. These include slicing preparation, thin film deposition, cleaning and inspection processes. In these processes, semiconductor equipment slip rings can be used for rotating slicing disks, vacuum rotary joints and various rotating support structures to achieve power supply, signal transmission and medium delivery.

- Technical requirements: Semiconductor equipment slip rings need to meet a series of strict technical requirements. First, it must have the characteristics of high-speed rotation, high-precision transmission and low noise to ensure the stability and reliability of the semiconductor manufacturing process. Secondly, semiconductor equipment slip rings need to have good electrical insulation and dust and pollution prevention properties to avoid negative impact on the quality of semiconductor products. In addition, corrosion resistance, wear resistance and reliable sealing are also key characteristics required of semiconductor equipment slip rings.

- Innovation and development: With the continuous development of semiconductor technology, semiconductor equipment slip rings are also constantly innovating and improving. For example, the use of brushless motors and contactless slip ring designs can reduce friction and wear and improve the reliability and life of the equipment. In addition, the application of new materials and the improvement of precision processing technology can also help improve the performance and reliability of semiconductor equipment slip rings.

In summary, semiconductor equipment slip rings are one of the indispensable core equipment in smart factories. They realize power transmission, signal transmission and medium flow between rotating parts in the semiconductor manufacturing process, ensuring the stable operation and high-quality manufacturing of semiconductor equipment. With the continuous advancement of semiconductor technology, semiconductor equipment slip rings will continue to innovate and develop to meet the needs of smart factories for higher performance and reliability.