The Revolutionary Liquid Slip Ring: The Future of Seamless Power and Data Transfer

In the ever-evolving world of advanced technology, the need for seamless power and data transfer has become paramount. Traditional slip rings have served as a crucial component in various industries, enabling the transfer of signals, power, and data between stationary and rotating parts. However, the limitations of conventional slip rings have spurred the development of a groundbreaking innovation – the liquid slip ring. This article explores the concept, benefits, and potential applications of this cutting-edge technology.

Understanding Liquid Slip Rings:

ᅠ ᅠ ᅠ ᅠ A liquid slip ring, also known as a rotating electrical joint, utilizes a unique design that replaces the traditional mechanical brushes and contacts found in conventional slip rings. Instead, it employs an innovative liquid-based solution to establish electrical connections between rotating and stationary parts.

ᅠ ᅠ ᅠ ᅠ The liquid slip ring consists of a rotating assembly and a stationary assembly. The rotating assembly is filled with a conductive liquid, such as mercury or a specialized conductive fluid, which acts as a medium for transferring electrical signals and power. As the rotating assembly turns, the conductive liquid forms an uninterrupted electrical pathway, ensuring reliable and continuous transmission.

Benefits of Liquid Slip Rings:

1. Enhanced Reliability: Unlike mechanical slip rings that suffer from wear and tear over time, liquid slip rings offer a longer lifespan due to the absence of brushes and contacts. The elimination of mechanical components reduces maintenance requirements and minimizes the risk of signal interruption or power loss.

2. Reduced Friction and Heat Generation: The liquid medium in these slip rings significantly reduces friction, resulting in smoother rotation and lower heat generation. This improved efficiency ensures optimal performance and reduces the likelihood of overheating, making liquid slip rings suitable for high-speed and high-power applications.

3. Increased Signal Integrity: The liquid medium in the slip ring provides a continuous and stable electrical connection, minimizing signal degradation and interference. This ensures reliable data and power transmission even in demanding environments with vibrations, shocks, or extreme temperatures.

Applications of Liquid Slip Rings:

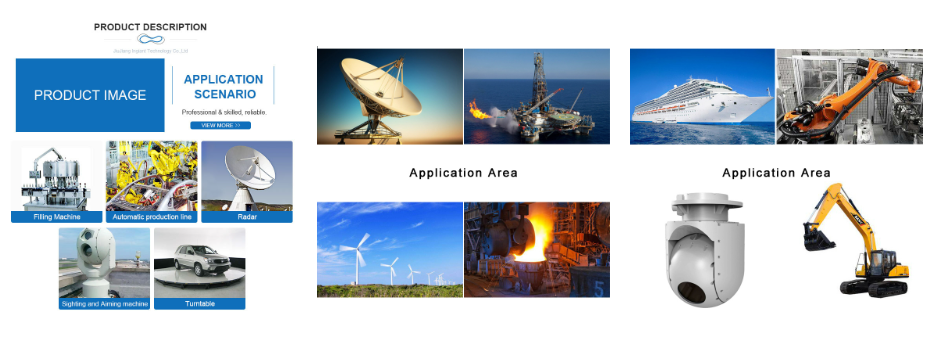

1. Robotics and Automation: In industries such as manufacturing, assembly lines, and robotic applications, liquid slip rings can enable seamless communication between rotating joints and stationary components. This ensures uninterrupted power supply and precise data transmission, improving the overall efficiency and reliability of automated systems.

2. Wind Turbines: Liquid slip rings are ideal for wind turbine applications, where they facilitate the transfer of electrical power and control signals from the rotating blades to the stationary components. The enhanced reliability and reduced maintenance requirements of liquid slip rings make them crucial for the smooth operation of wind energy systems.

3. Medical Equipment: Liquid slip rings find applications in medical devices, where they allow for the transmission of power and data between rotating parts, such as rotating X-ray machines or robotic surgical systems. The improved reliability and reduced friction of liquid slip rings offer seamless operation critical to medical procedures.

The liquid slip ring represents a significant leap forward in the field of power and data transmission, offering enhanced reliability, reduced friction, and improved signal integrity. This revolutionary technology has the potential to revolutionize various industries, including robotics, renewable energy, and healthcare. As the demand for seamless power and data transfer continues to increase, the liquid slip ring emerges as a game-changing solution that bridges the gap between rotating and stationary components, propelling industries towards a more efficient and reliable future.