The role and application areas of low-pressure slip rings

Low-voltage slip ring, also called low-voltage rotary joint or rotary electrical contact, is a rotary connection device used to transmit low-voltage signals and small currents. It usually consists of a stator and a rotor. Low-voltage slip rings are different from high-voltage slip rings in that their voltage level is usually below 250V and the current is in the milliamp level. Usually used in low power environments with low rotational speed. This type of slip ring is mainly used for signal transmission and the transmission of electrical signals. Low-voltage slip rings usually use advanced conductive materials to ensure the stability and accuracy of signal transmission.

The working principle of the low-voltage slip ring is to transmit signals or small currents from the fixed end to the rotating end through a rotating transmission device. Usually, the fixed end of the low-voltage slip ring is fixed in the casing by a steel ring or copper ring, and the rotor is an electrode or sliding joint that matches the rotating machine. The rotor axis and the fixed end axis are consistent and rotate. In this way, low voltage signals or small currents can be transmitted from the fixed end to the rotor end through rotation.

One of the advantages of low-pressure slip rings is their lower cost of use. Because the design of low-pressure slip rings is relatively simple, manufacturing and maintenance costs are relatively low. In addition, low-pressure slip rings are relatively convenient to arrange and install due to their smaller size and volume.

Low-voltage slip rings also have some disadvantages: they are limited in the transmission range of voltage and power and cannot cope with high-voltage and high-power requirements.

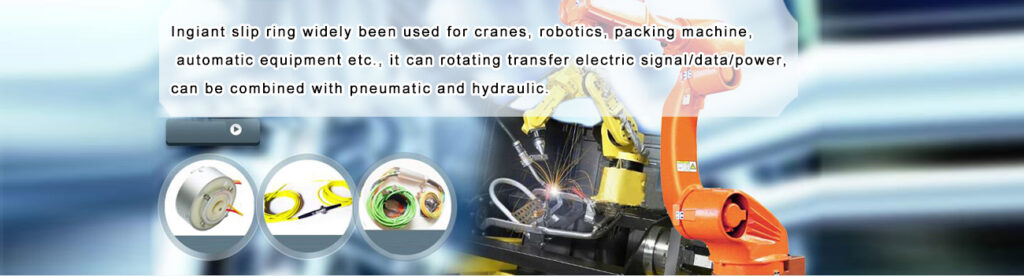

Low-voltage slip rings are widely used in industrial production, manufacturing, aerospace, medical equipment and many other fields. With the development of science and technology, low-voltage slip rings also have important applications in industries such as robots, automated production lines, and wind power generation.