What Is Pancake Slip Ring?

The pancake slip ring is similar to through hole slip ring but is especially used for the rotating system with a height limit. Also called flat slip ring, flat disc electrical slip ring, or platter slip ring, since the shape is similar to a platter, rings, and brushes contact around the center of the circle. Pancake slip ring components include stator, rotor, and contacts, mainly used for transmitting precise signals and power or combined with pneumatic and hydraulic media. More electrical power, current, and signal circuits can extend broadwise limitless on flat diameter.

Pancake slip rings can be configured in two types, integrated and separated.Integrated rings type can be designed for solid or through hole rotating systems.The separated ring type is composed of a separated rotor and contact brush, which can be designed with PCB.

Use of the Pancake Slip Rings

Pancake slip rings have found extensive use across a variety of industries due to their unique design, structure, and ability to operate in a range of environments. They serve as an adaptable, flexible solution for providing uninterrupted power and signal transmission between stationary and rotating platforms, particularly when vertical space is at a premium.

Pancake slip rings are predominantly engaged across many sectors due to their ability to fulfill diverse power and signal transmission requirements. They can be found in automotive, aerospace, marine, healthcare, communication, manufacturing, and many more industries. Here are some key applications where pancake slip rings shine:

Cable Reels

Cable reels, commonly used in the entertainment and broadcasting industry, require reliable rotational contact solutions to facilitate smooth transmission of signals. Pancake slip rings, with their compact dimensions and optimized electrical transmission capabilities, are ideal solutions for such devices.

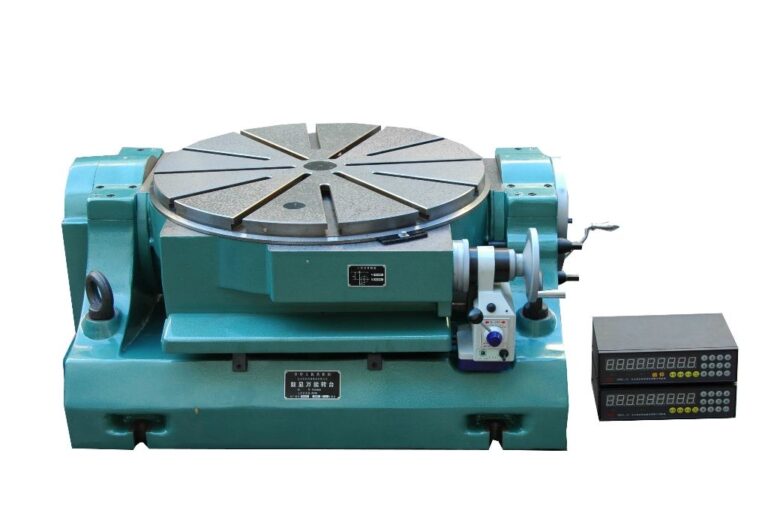

Rotary tables

In manufacturing or imaging equipment, rotary tables need to rotate smoothly while consistently transmitting power and signals. The space-saving designs of pancake slip rings, coupled with their reliable performance, make them perfectly suitable in these situations.

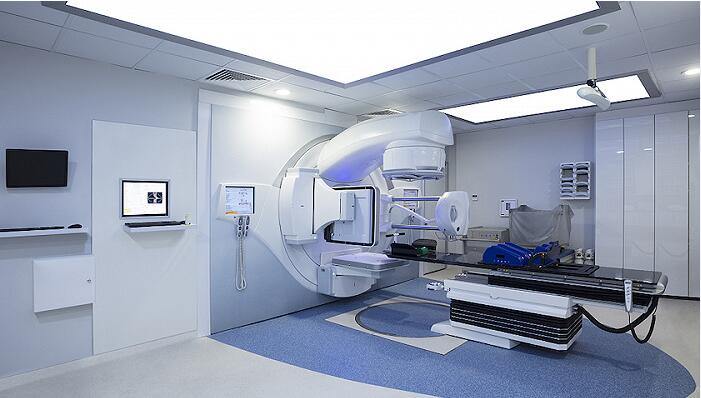

Medical Imaging Machines

In precise medical applications such as MRI and CT scanners, transferring high-quality data from the rotating parts to stationary systems with no interruption is critical. Given their compact structure and superior performance, pancake slip rings are often found in these imaging machines.

Radar Systems

Radar systems necessitate continuous data and power transmission for accurate tracking and communication, additionally followed by space constraints. The flat design of the pancake slip rings coupled with the capability for high-frequency data transmission makes them an ideal choice.

Closed-circuit Cameras

Any disruption or lag in signal transmission in surveillance systems can have serious repercussions. Pancake slip rings installed in closed-circuit cameras ensure uninterrupted, smooth signal transmission even when the cameras are constantly rotating.

Advantages of the Pancake Slip Rings

With their unique design and structure, pancake slip rings offer a plethora of advantages that not only make them superior to cylindrical slip rings in certain applications but also enable them to cater to a wide range of industries and sectors.

1:Minimized Vertical Space Requirement

The flat, compact design that is the hallmark of pancake slip rings significantly reduces vertical height, making them perfect for applications with restricted vertical space. This proves advantageous in numerous industries like automotive, medical, and aerospace, where space often comes at a premium.

2.High Capacity for Circuits

Despite their compact structure, pancake slip rings can house a large number of concentric circuits. The larger the diameter, the more circuits it can accommodate. Hence, the information and power transmission capabilities are not compromised, contrary to what one might expect given their small size.

3.Customizability

Pancake slip rings can be custom-engineered to suit various electrical and mechanical requirements. This edge in customizability includes modifications for current and voltage ratings, temperature ranges, and making the slip ring resistant to certain environmental conditions, making pancake slip rings versatile across applications.

4.Durability

Most pancake slip rings are produced using quality materials and possess a robust structure that makes them resilient to mechanical vibrations and shocks. This enhances their durability and reliability in arduous and challenging operating environments.

5.Simplified Integration

Their compact and simplistic design, combined with the capacity for customization, makes pancake slip rings easy to integrate within existing systems. This can prove advantageous in industries like manufacturing and automation, where any modification in machinery can disrupt operations.

Despite having several advantages, it’s important to note that pancake slip rings may not always be the optimal choice for all scenarios. They require regular maintenance due to the increased wear from their radial brush system, and in some applications, the increased diameter could also pose challenges. However, their unique design and structural advantages make them a valuable addition to many industries that deal with space constraints and complex power and signal transmission needs. In essence, the advantages of pancake slip rings significantly contribute to their popularity in multiple sectors.